How to create a Work order for Base Maintenace Shop

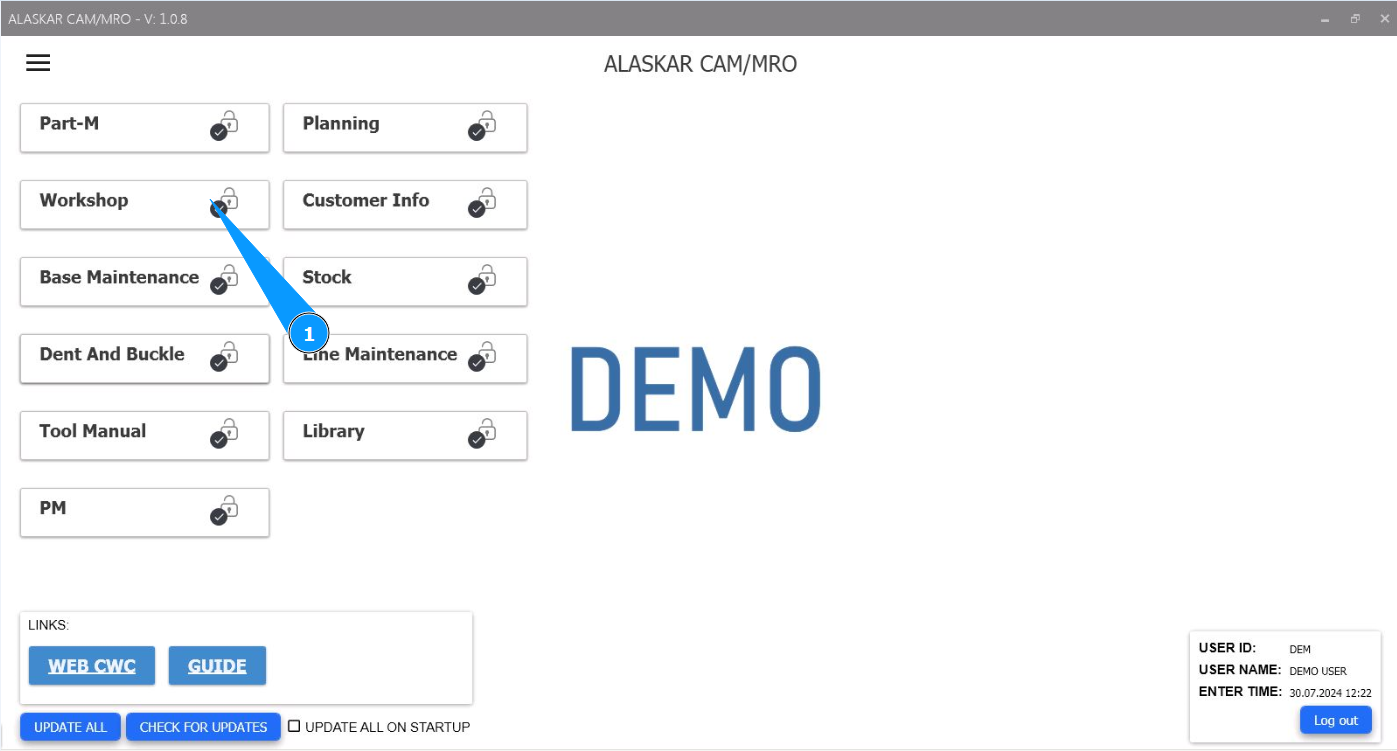

1. In order to create a work order for base maintenance (Base Maintenace Shop WO), go to the module "Workshop".

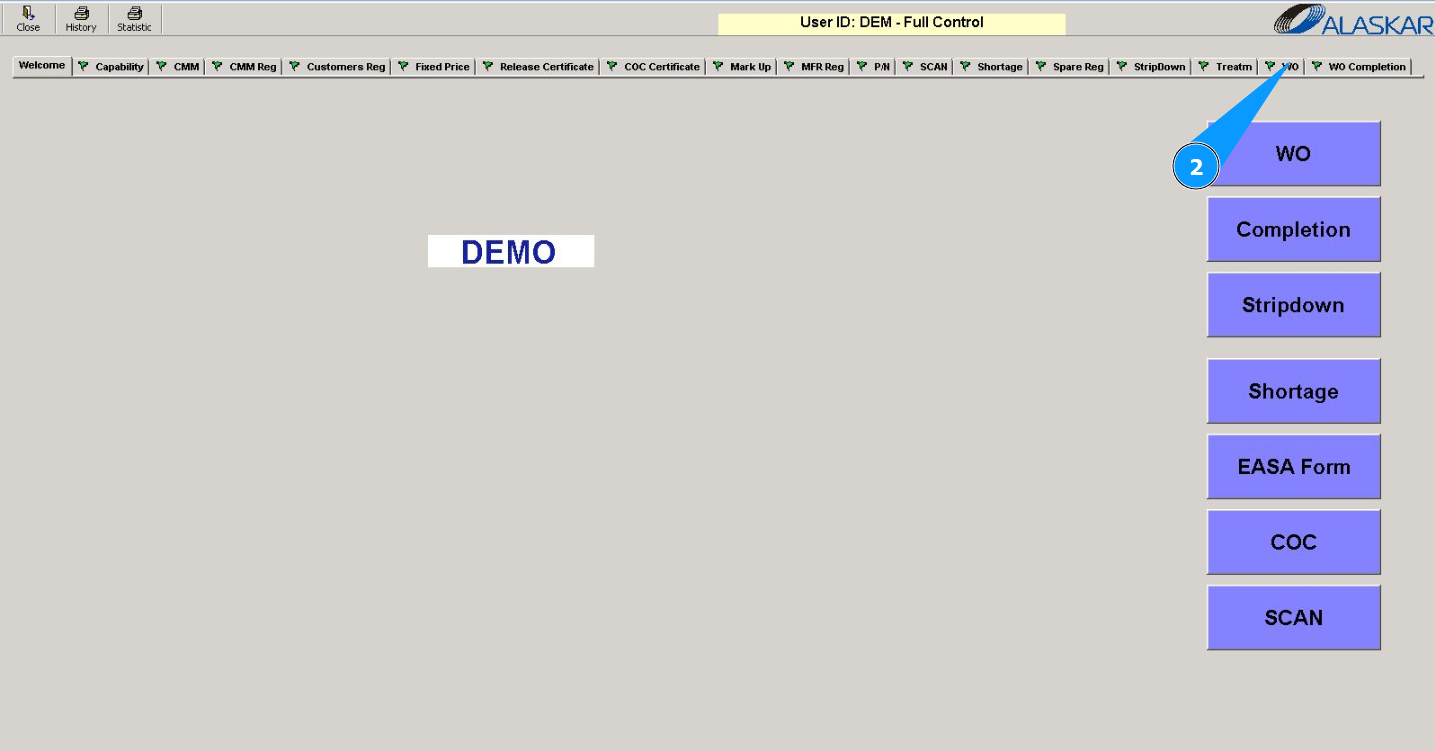

Note: Creating a Base Maintenace Shop WO is possible from the tab "WO" or via using the submodule "WO".

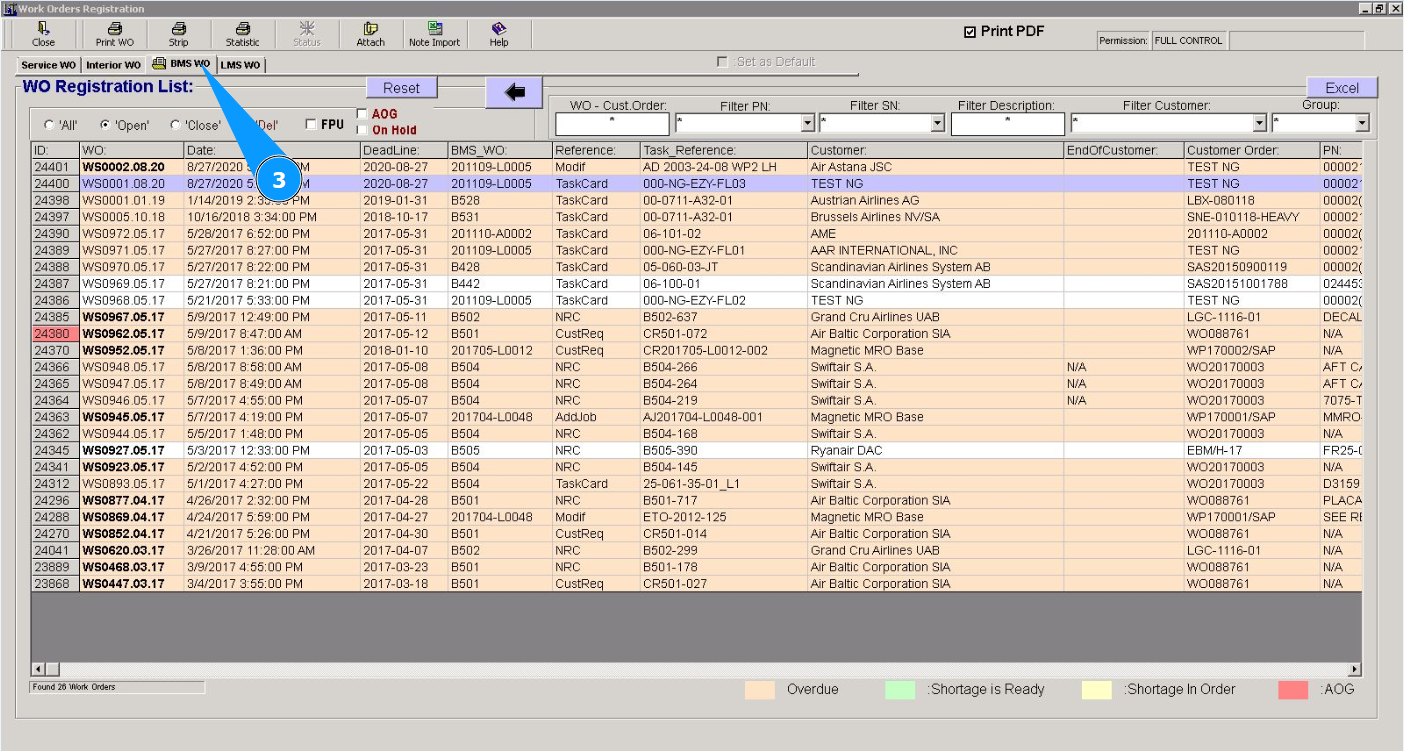

3. Then go to the tab "BMS WO".

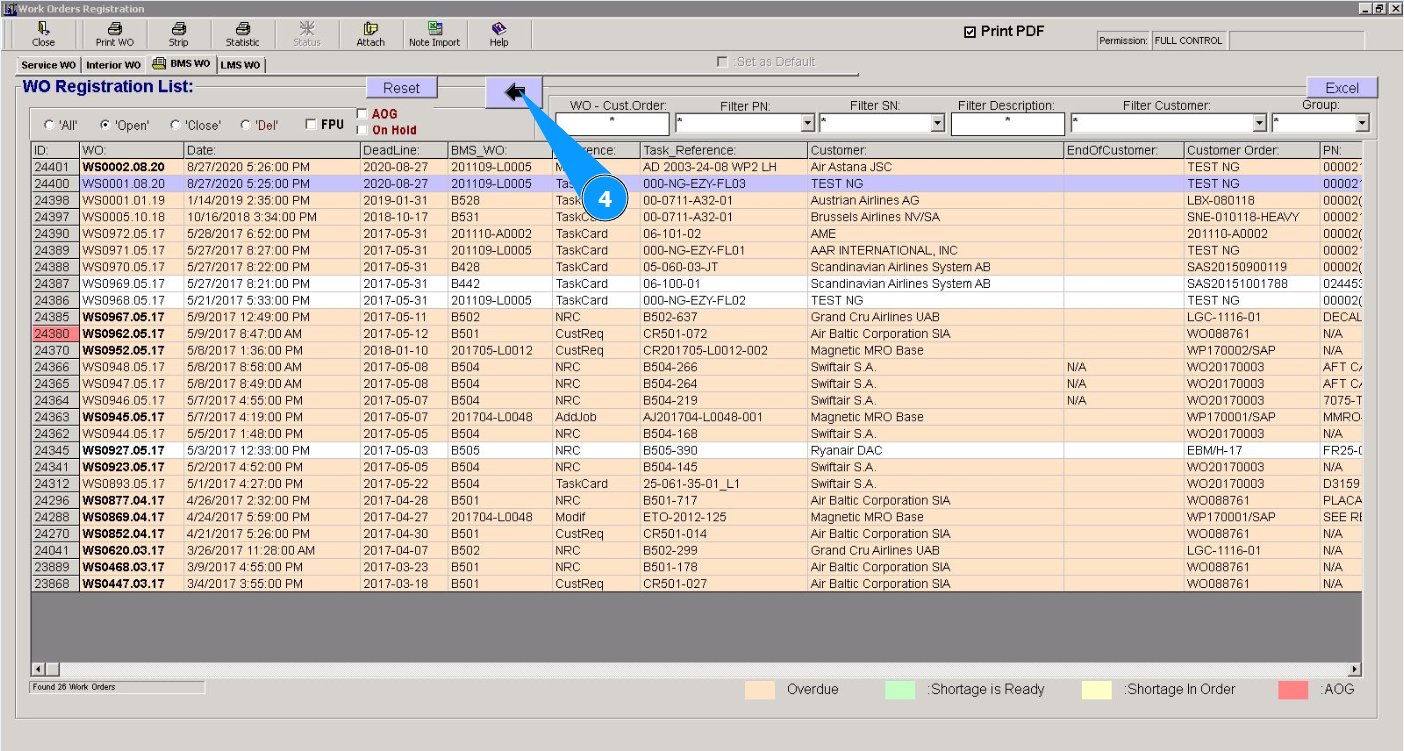

4. Click on the button with arrow to open the Base Maintenace Shop creation editor.

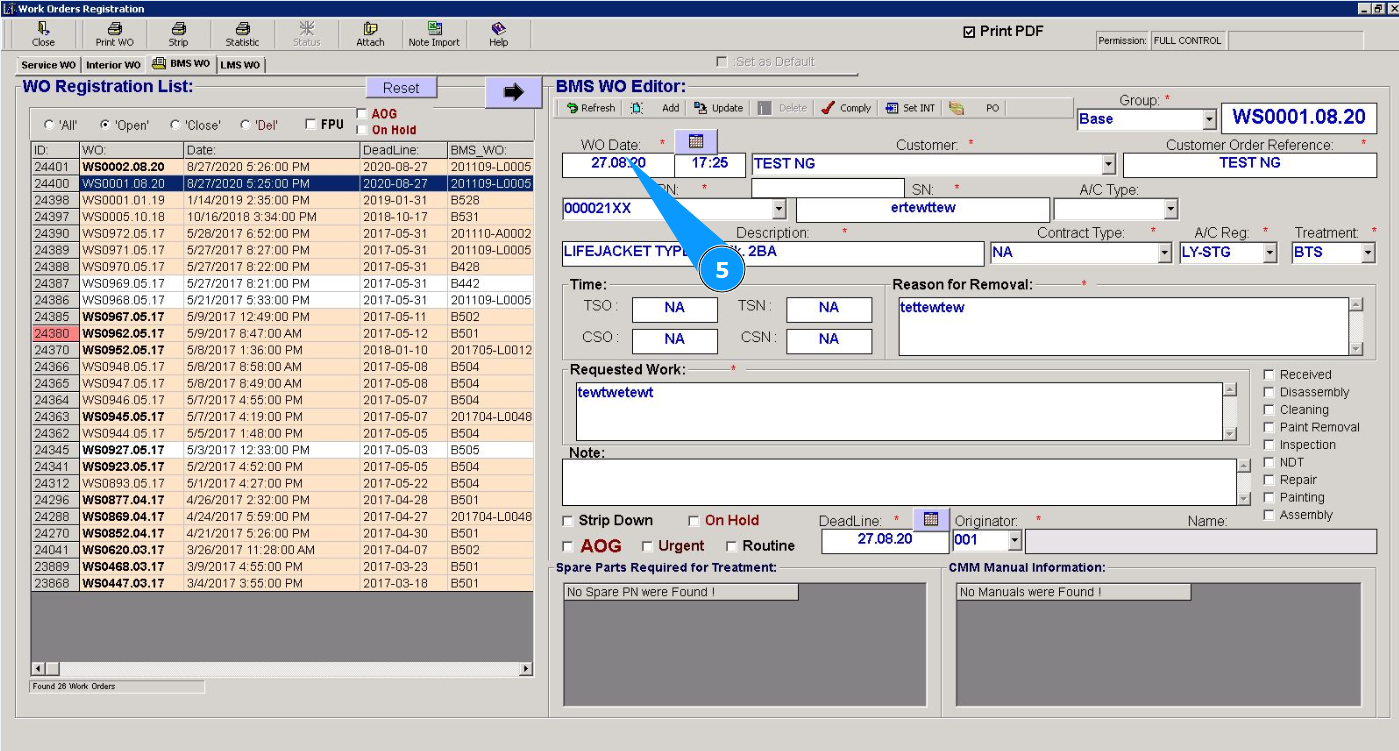

5. The creation date of Base Maintenace Shop work order is set to today's date by default. If necessary, change it in the calendar. Note: The work order number will be created automatically by the program.

6. Enter the time when the work order was created.

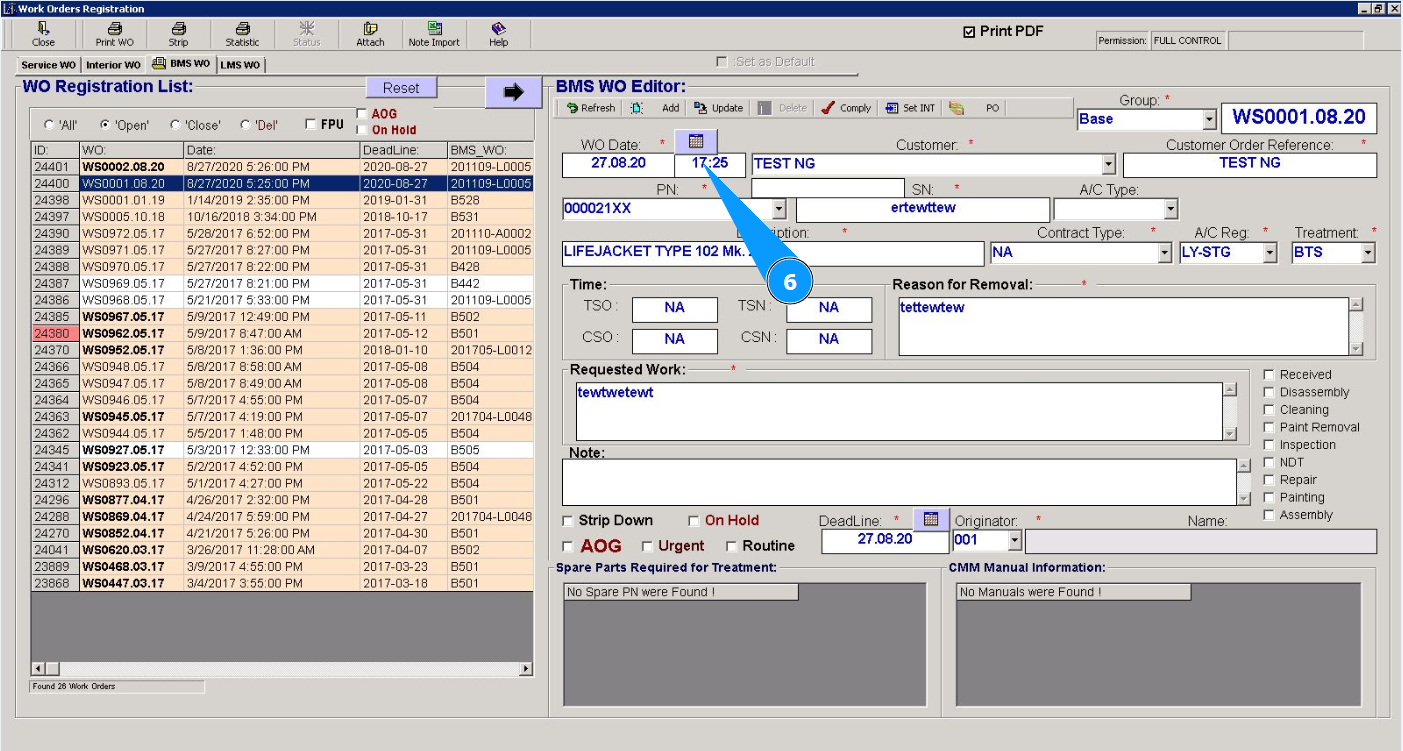

7. Select the work order group from the dropdown list in the field "Group".

8. Select the company name from the dropdown list in the field "Customer".

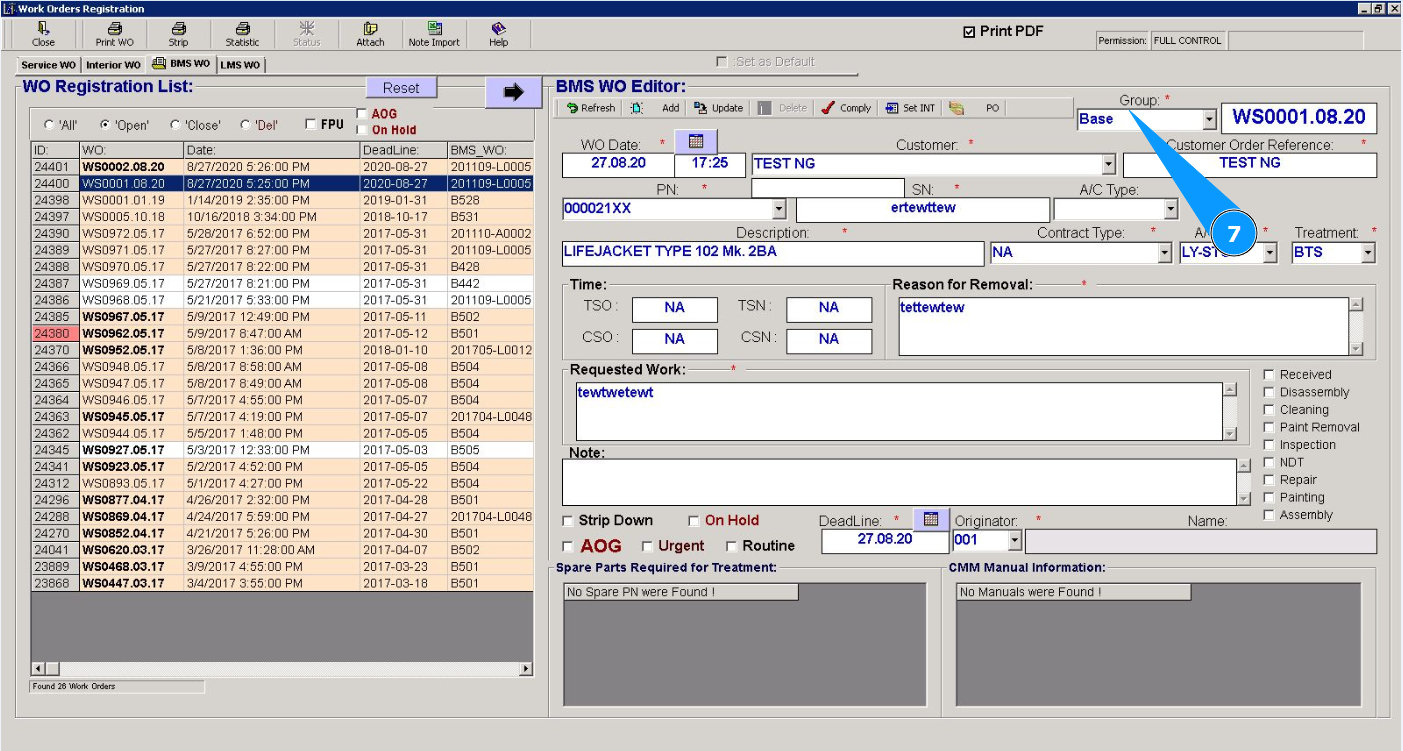

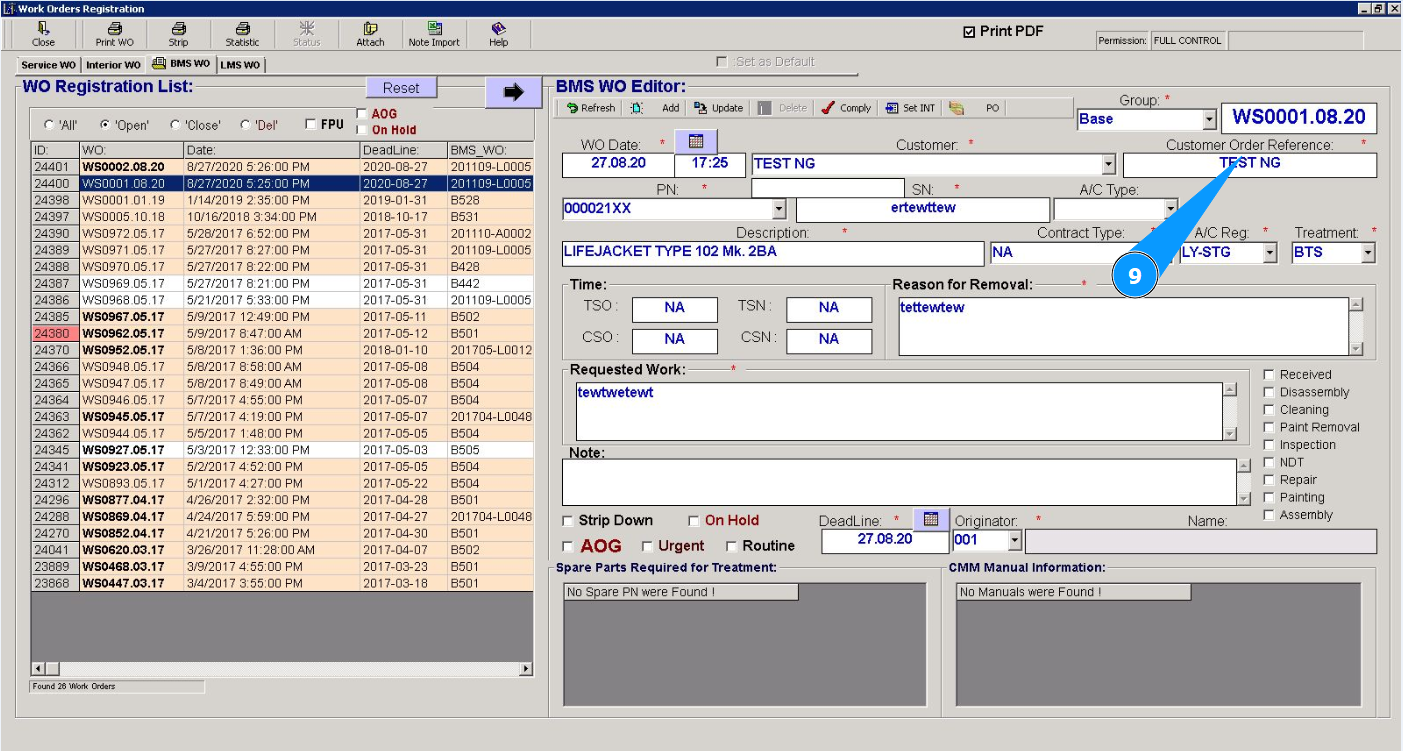

9. Enter a link to the ordernumber or customer order number in the field "Customer Order Reference".

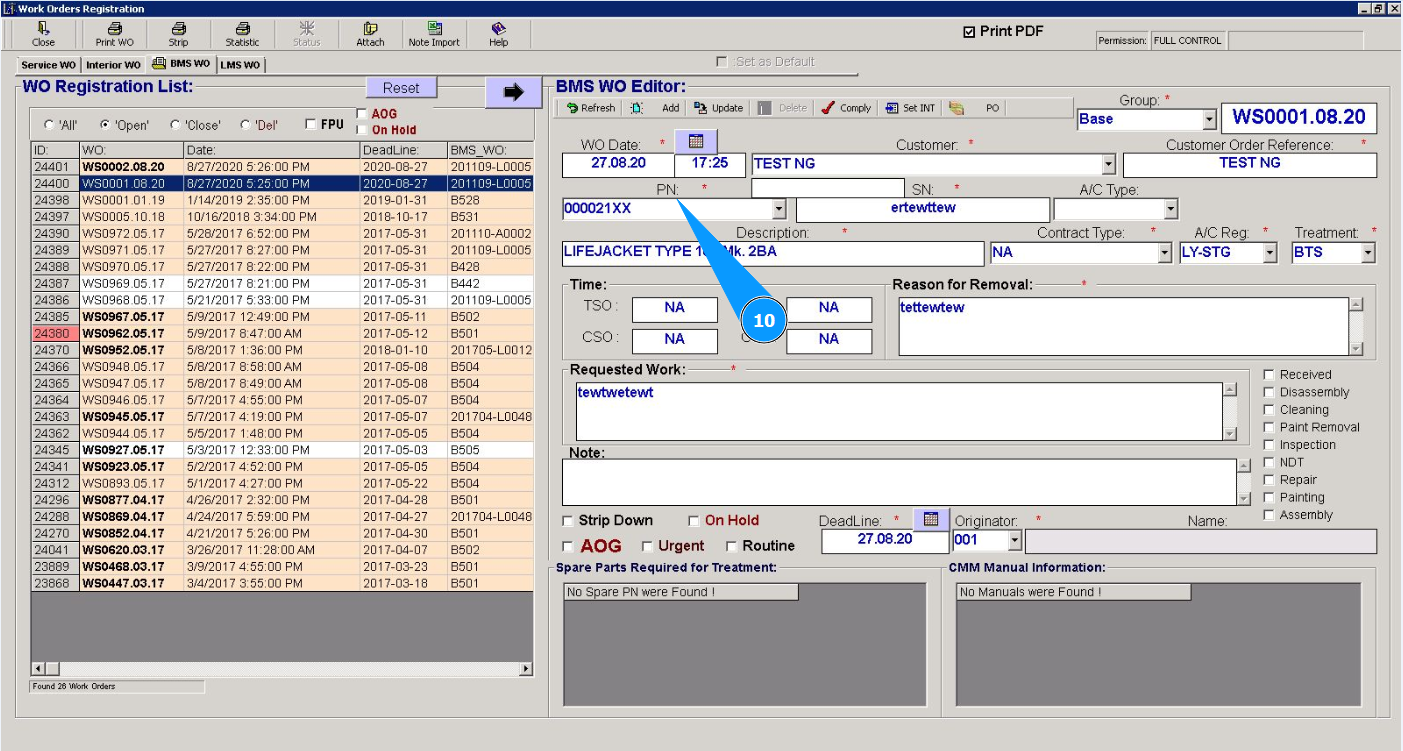

10. Select from the dropdown list the batch number of the product to perform the work in the field "PN". Note: The description of the selected component will be entered by the program automatically in the field "Description".

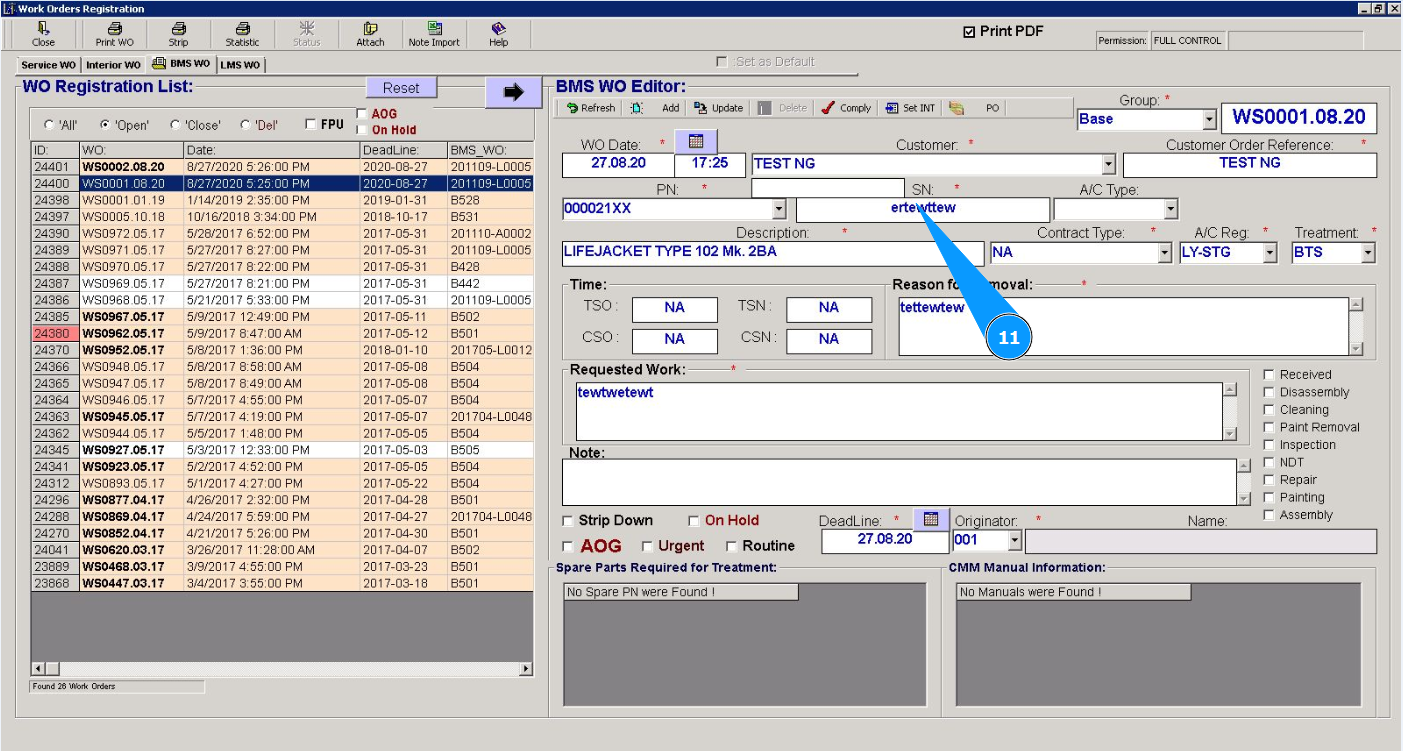

11. Enter the serial number of the product to perform the work in the field "SN".

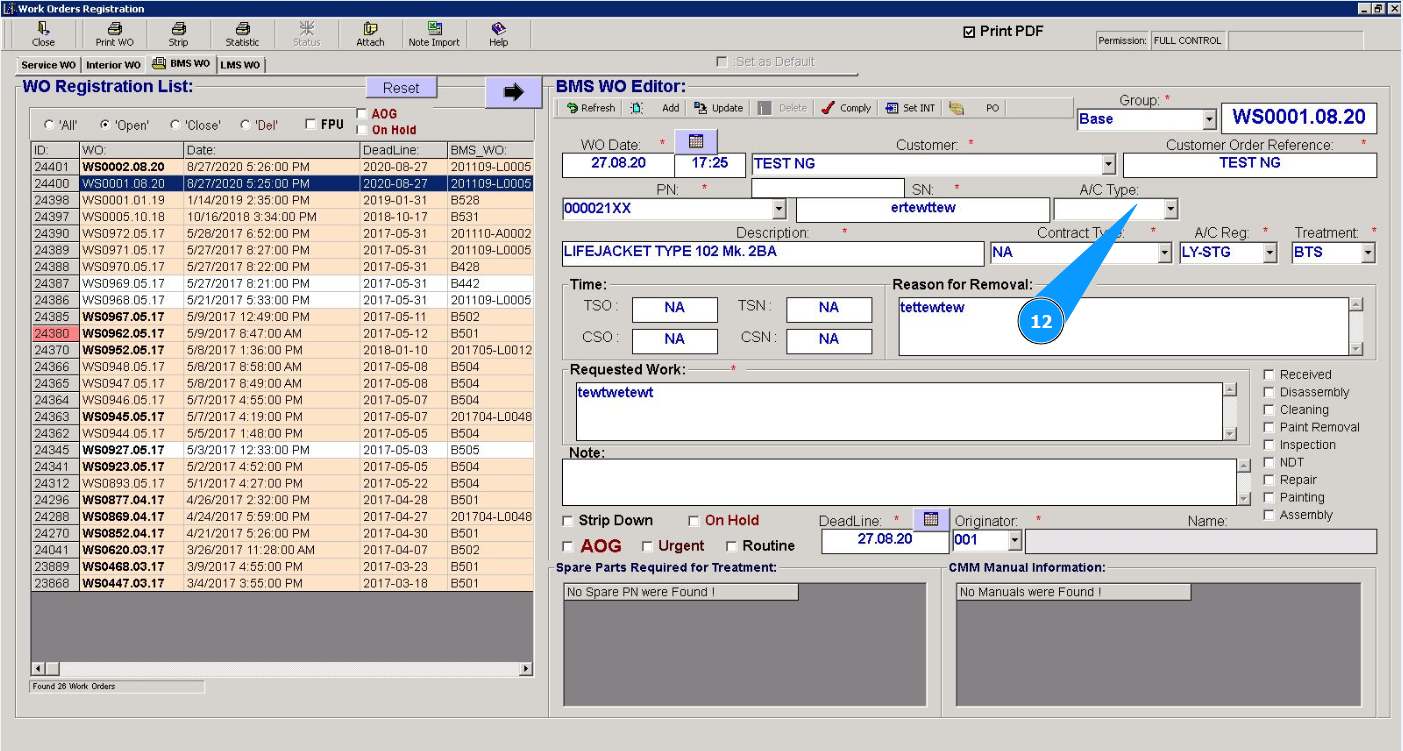

12. Select the aircraft type from the dropdown list in the field "A/C Type.

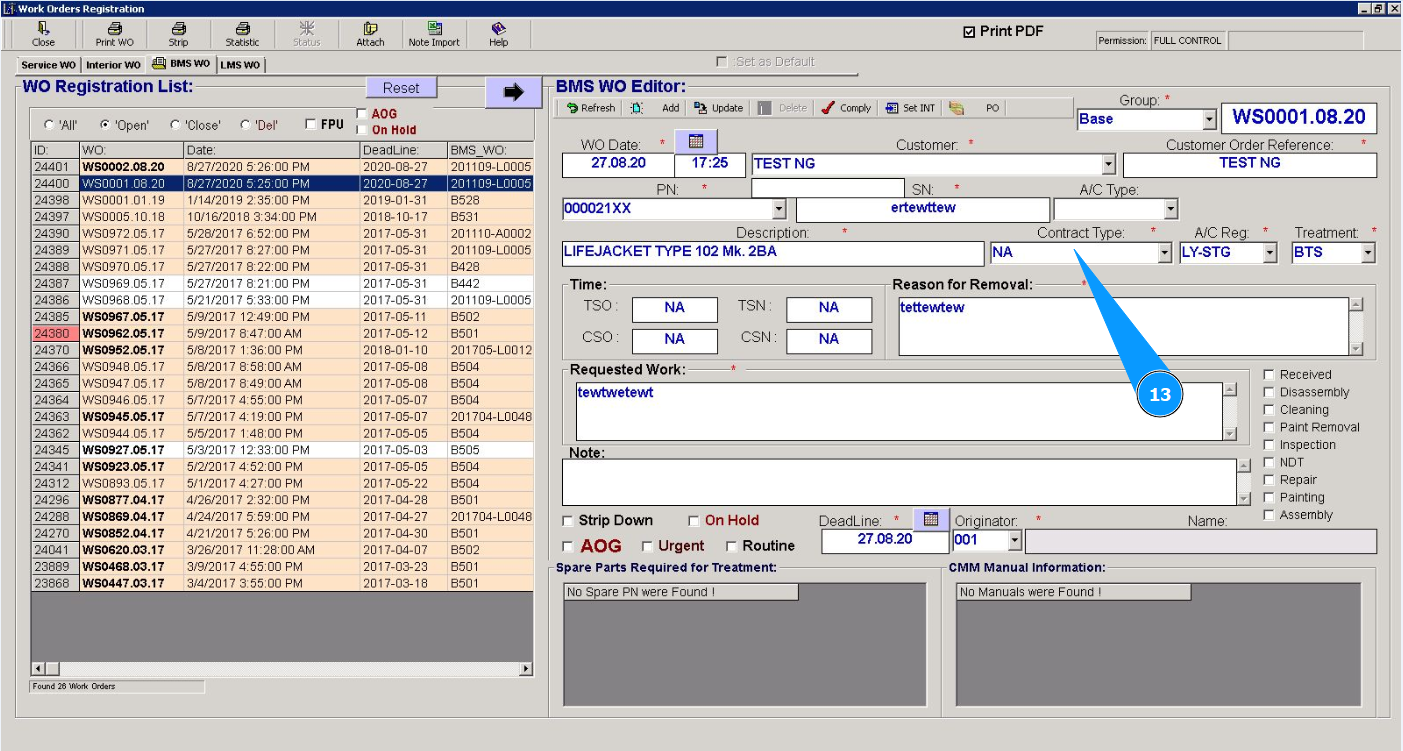

13. Select the contract type from the dropdown list in the field "Contract Type.

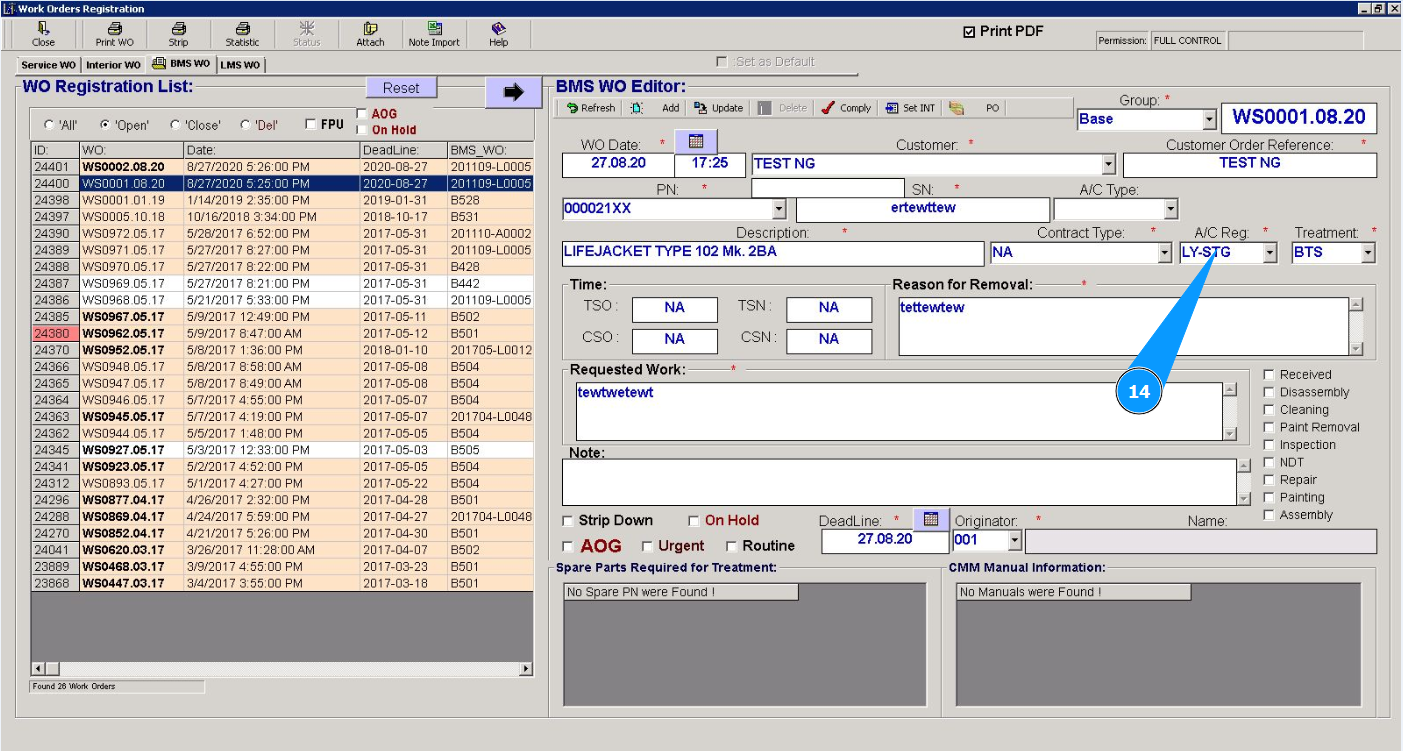

14. Select the aircraft registration number from the dropdown list in the field "A/C Reg..

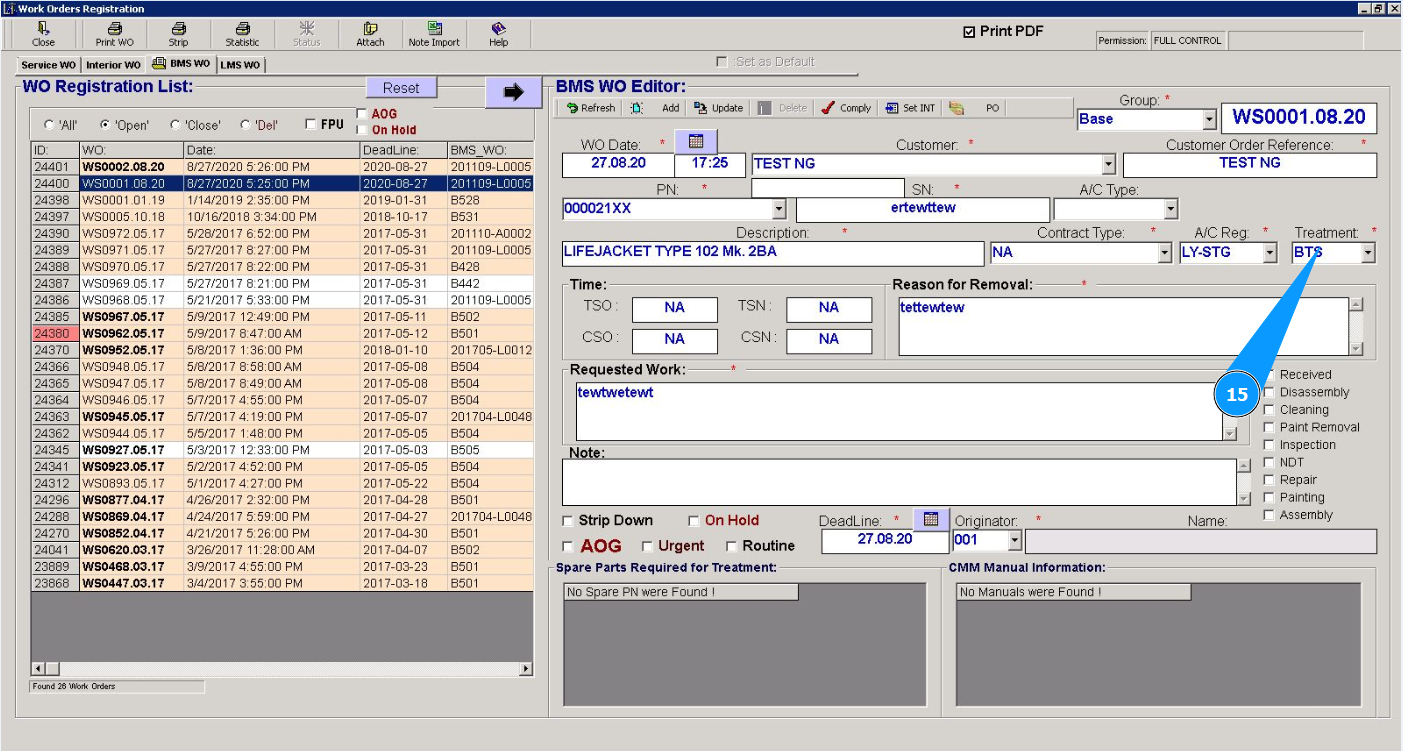

15. Select the required type of work from the dropdown list in the field "Treatment.

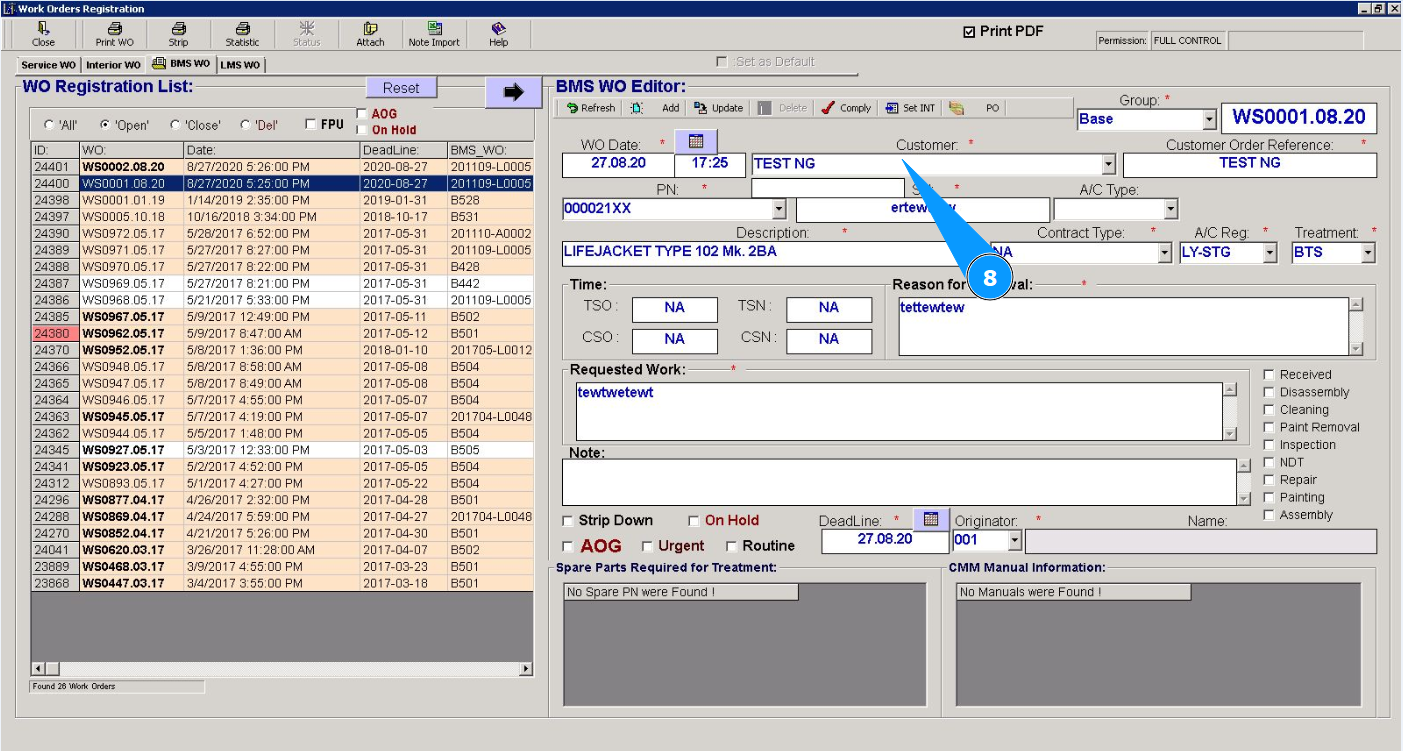

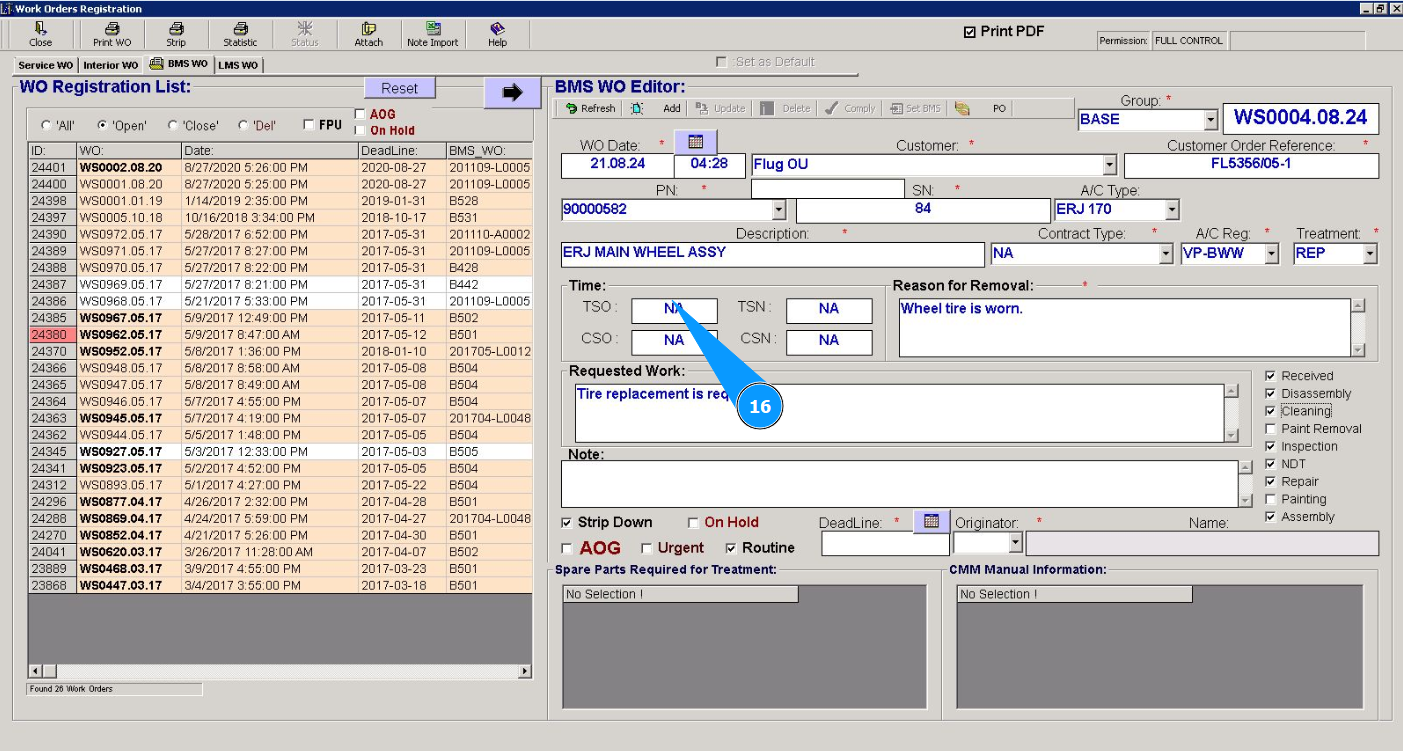

16. If necessary, enter the operating time of the component since the last major overhaul in hours in the field "TSO".

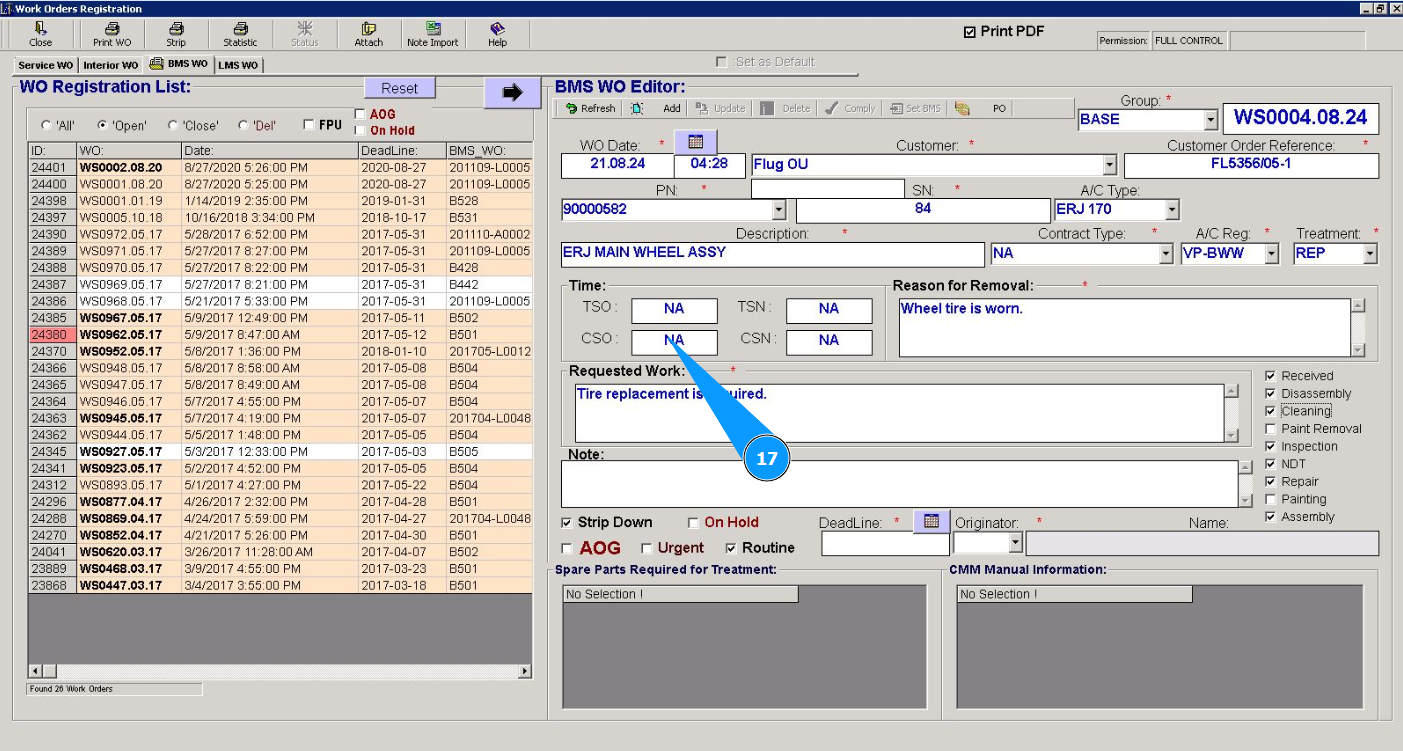

17. If necessary, enter the operating time of the component since the last major overhaul in cycles in the field "CSO".

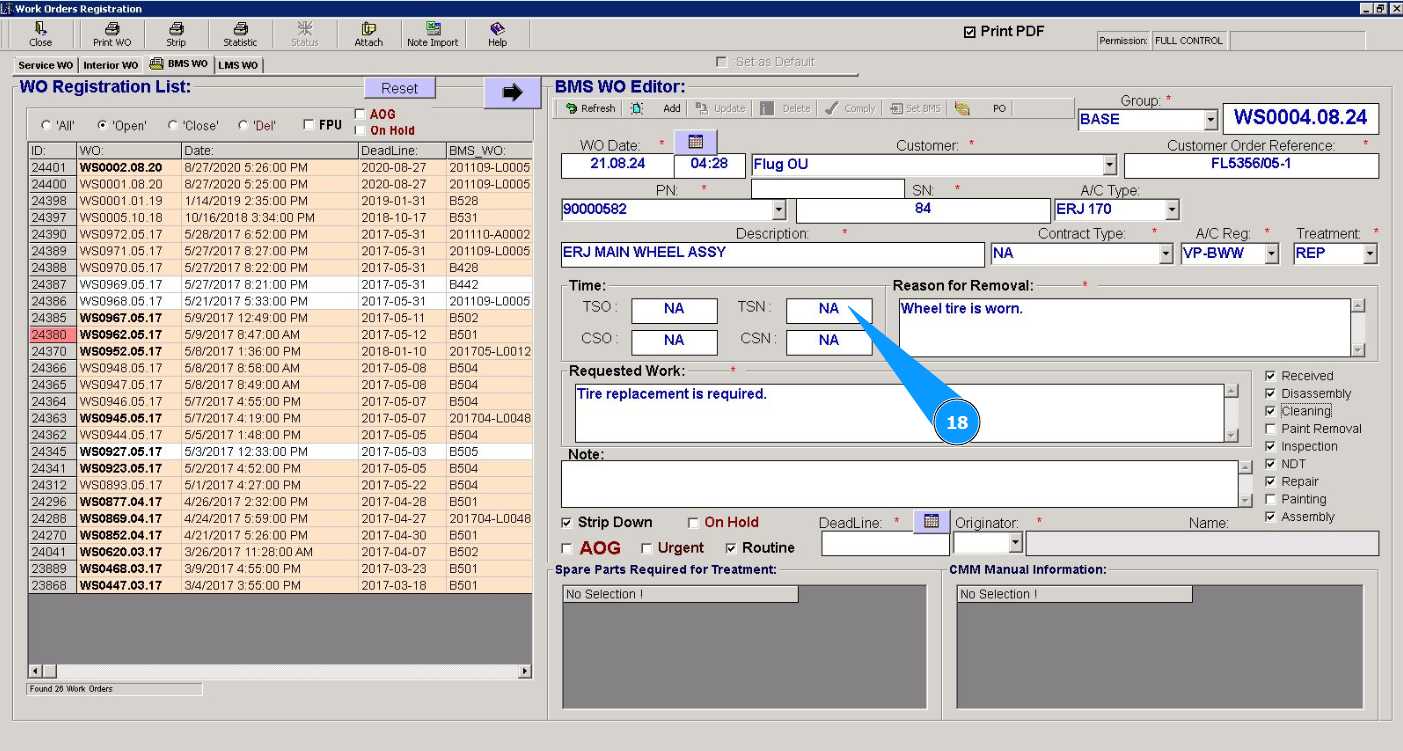

18. If necessary, enter the operating time of the component from the production date in hours in the field "TSN".

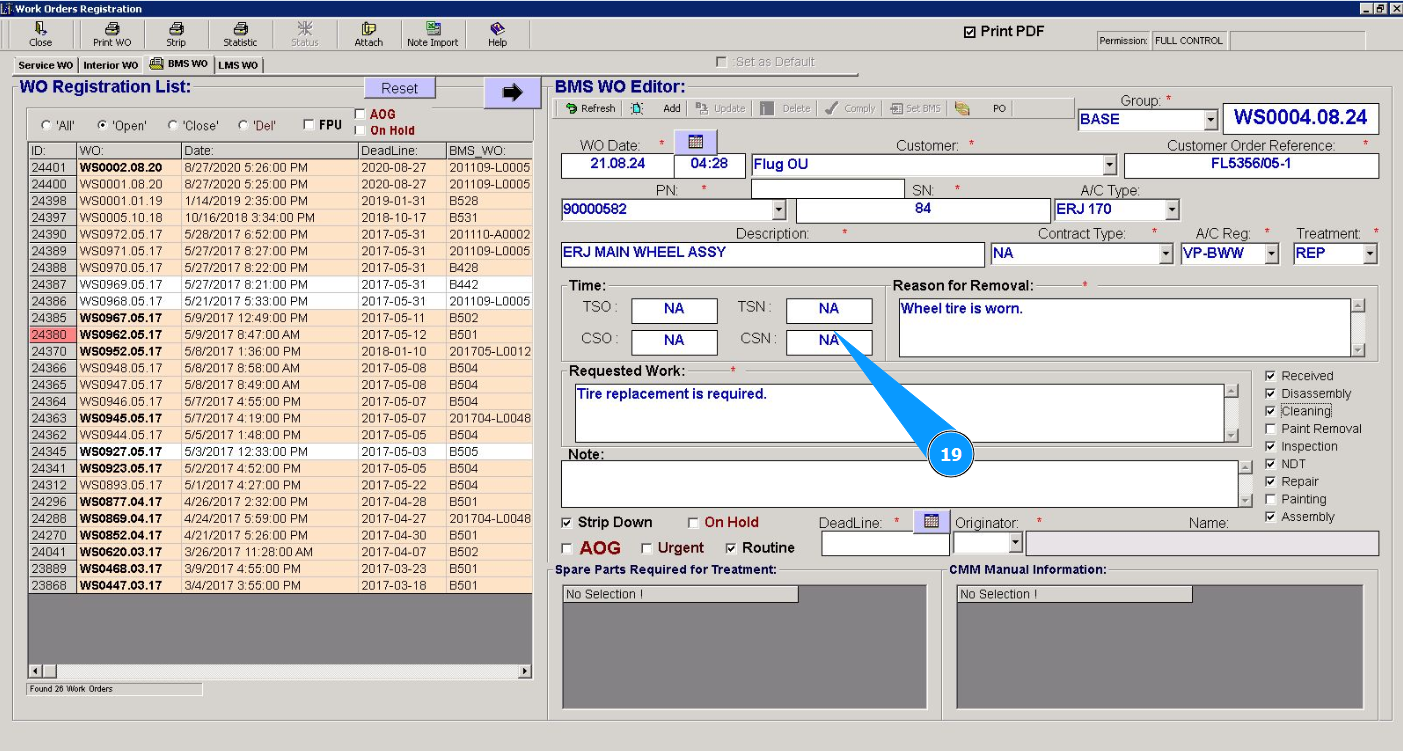

19. If necessary, enter the operating time of the component from the production date in cycles in the field "CSN".

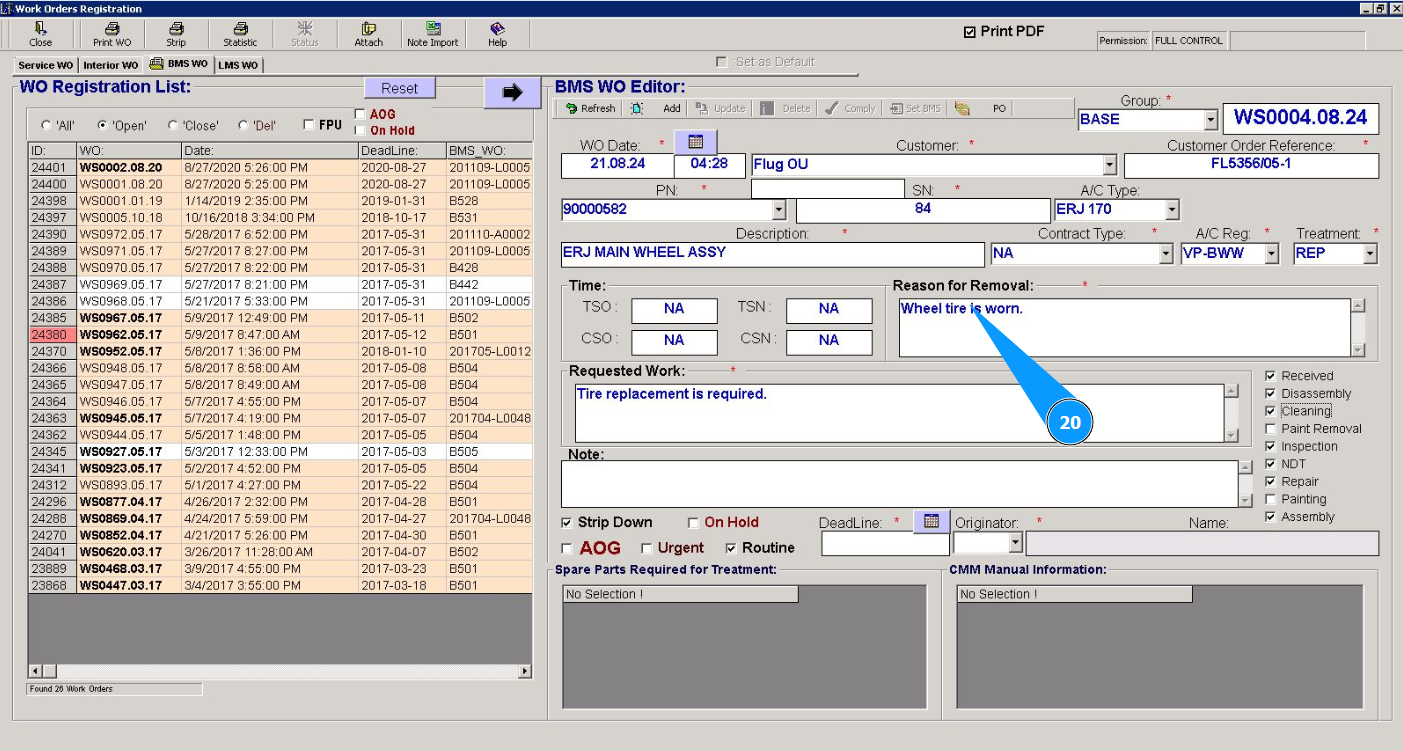

20. Enter the reason for removing the component in the field "Reason of Removal".

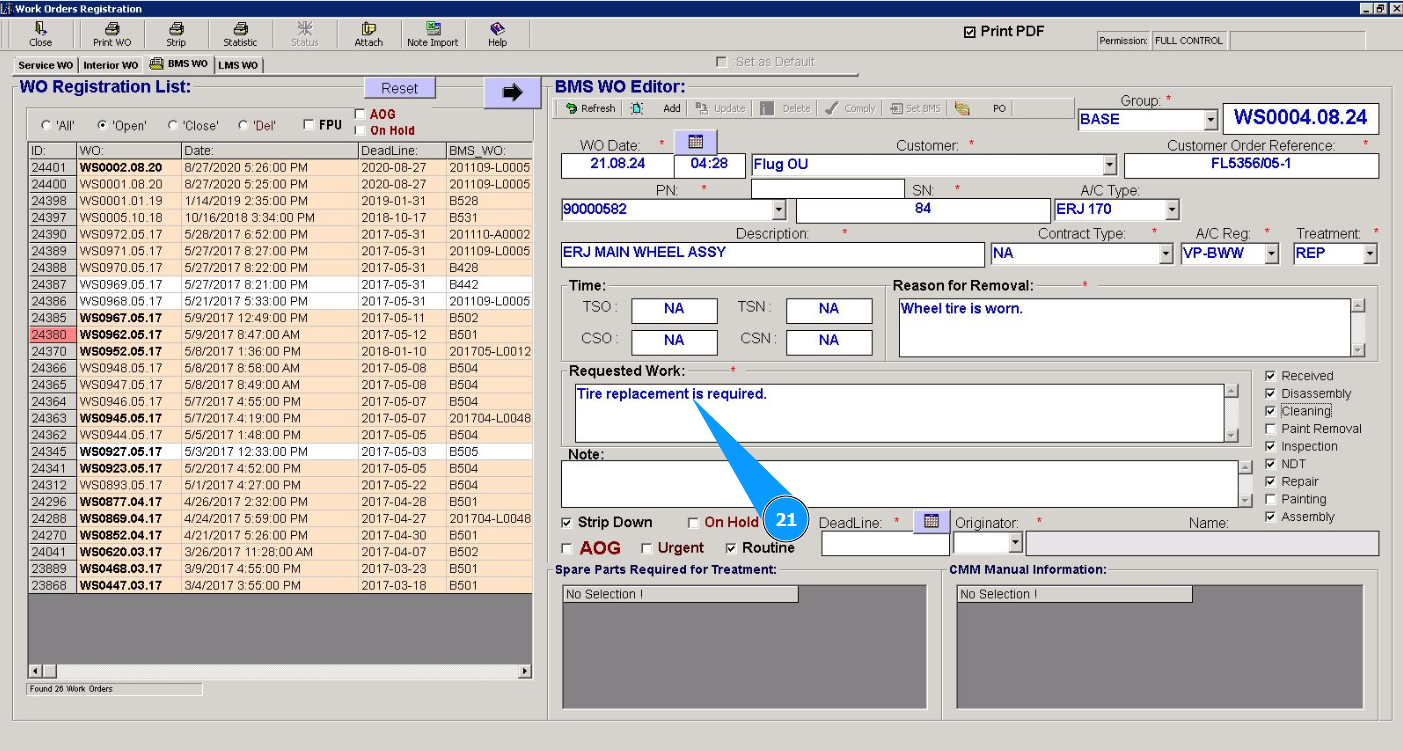

21. Enter the required work in the field "Requested Work".

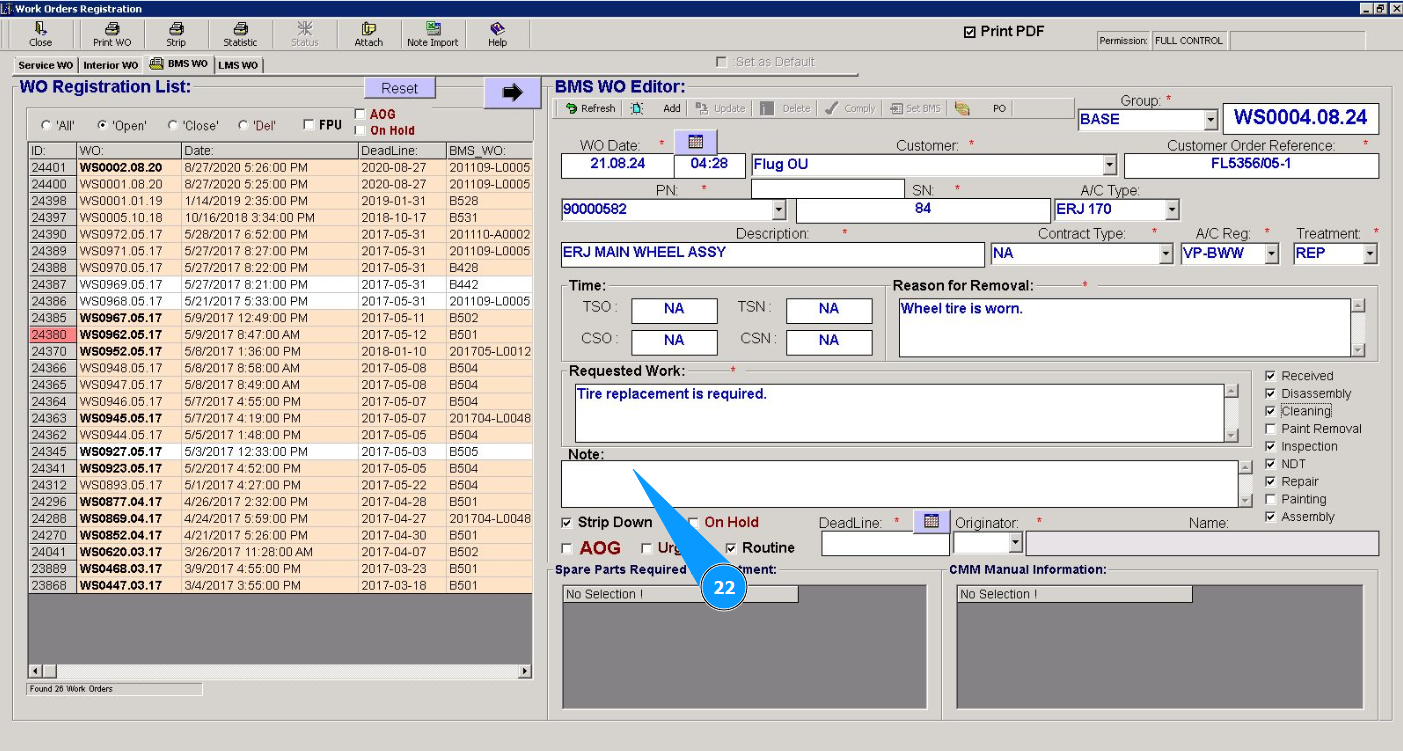

22. If necessary, enter comments in the field "Note".

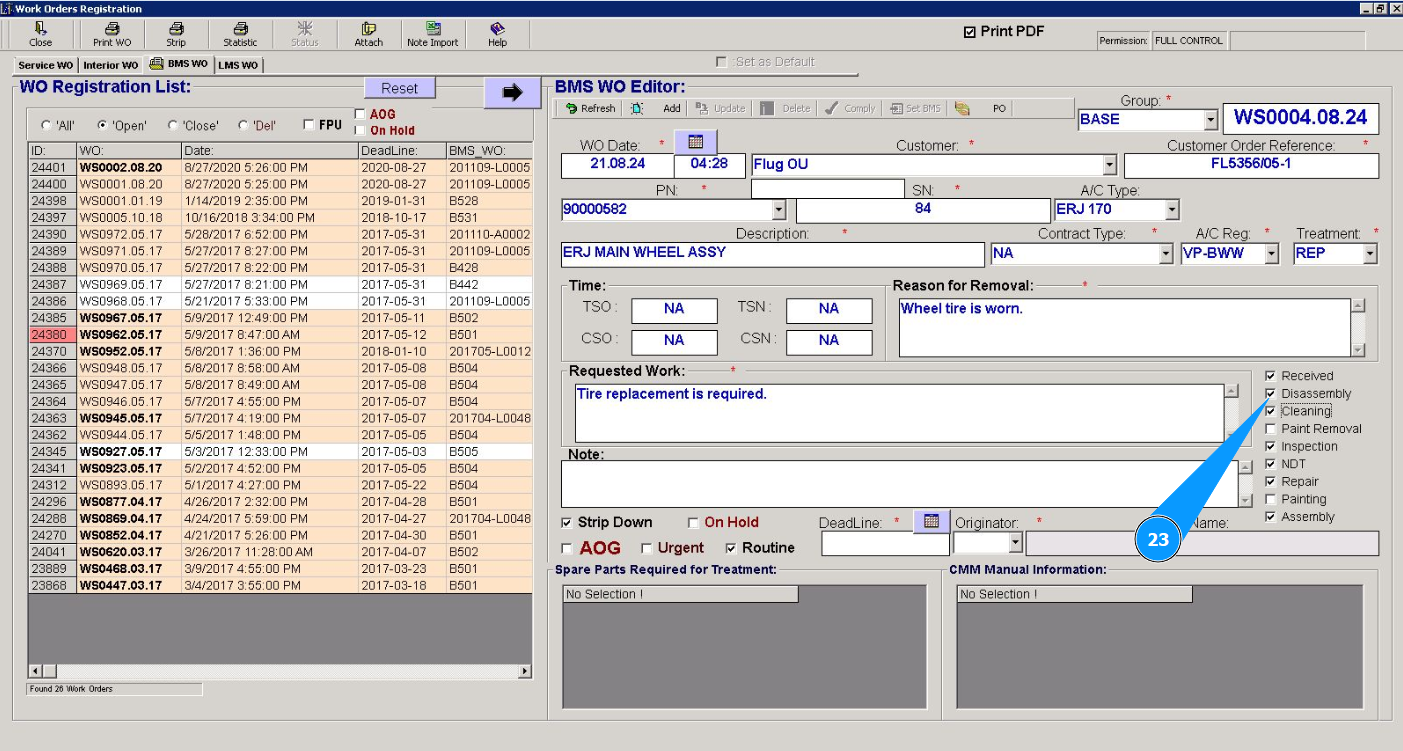

23. Select the required types of work and click in the appropriate window.

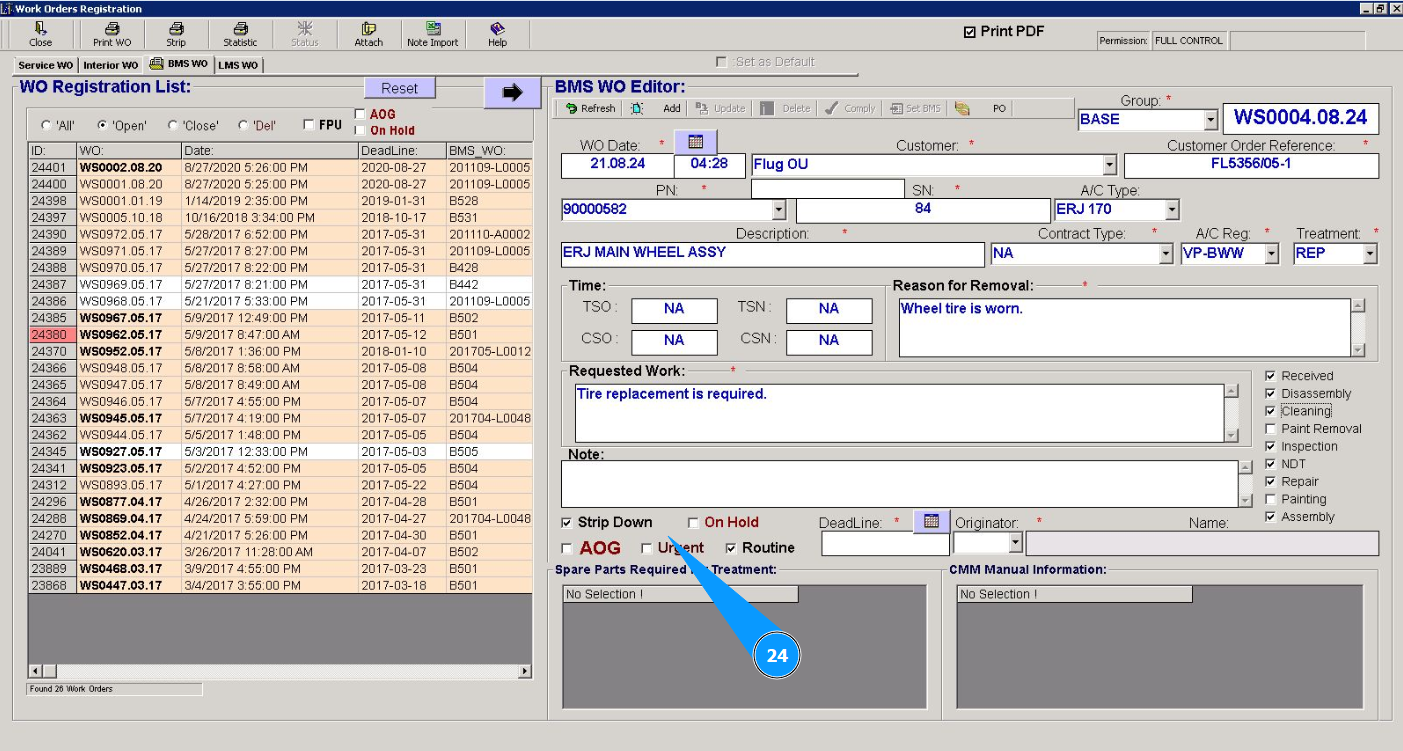

24. If necessary, select the required work criteria and click in the appropriate window.

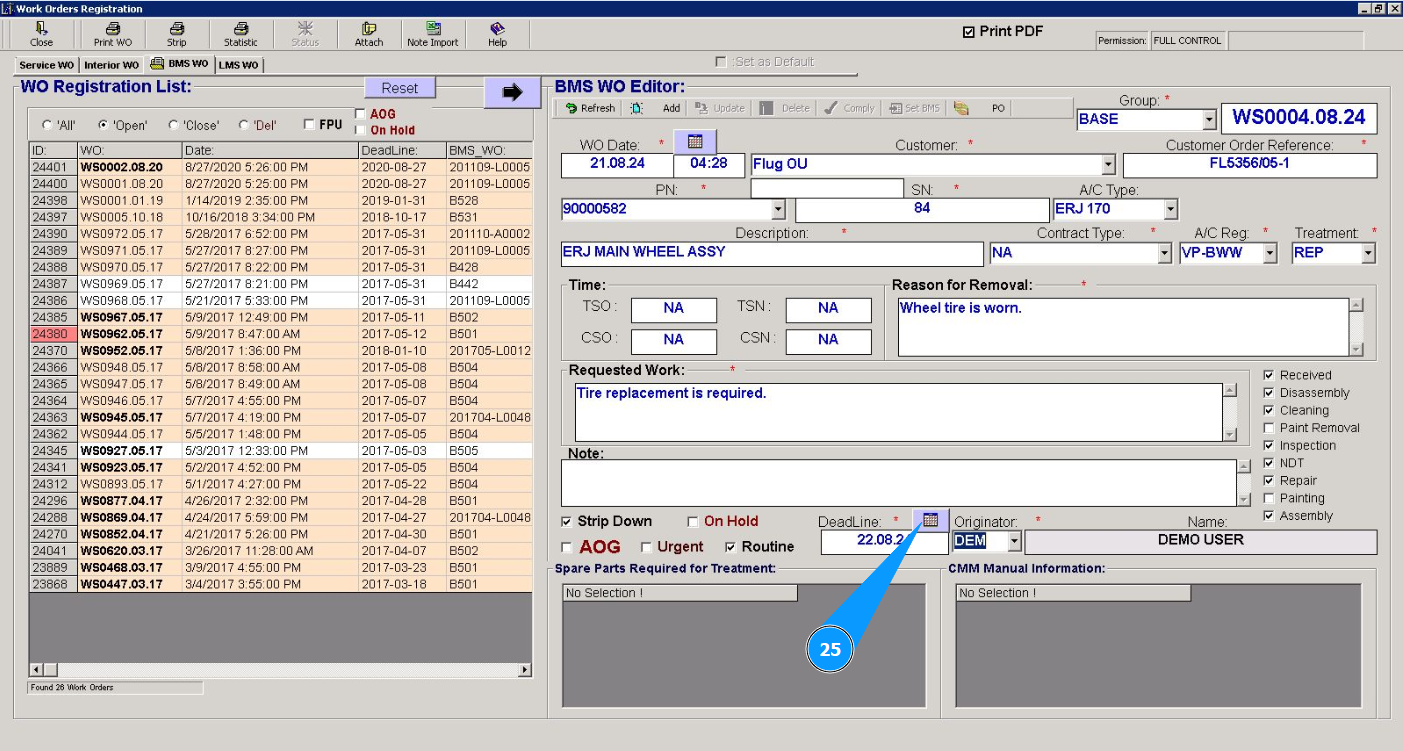

25. Select the work limitation date from the calendar in the field "Deadline".

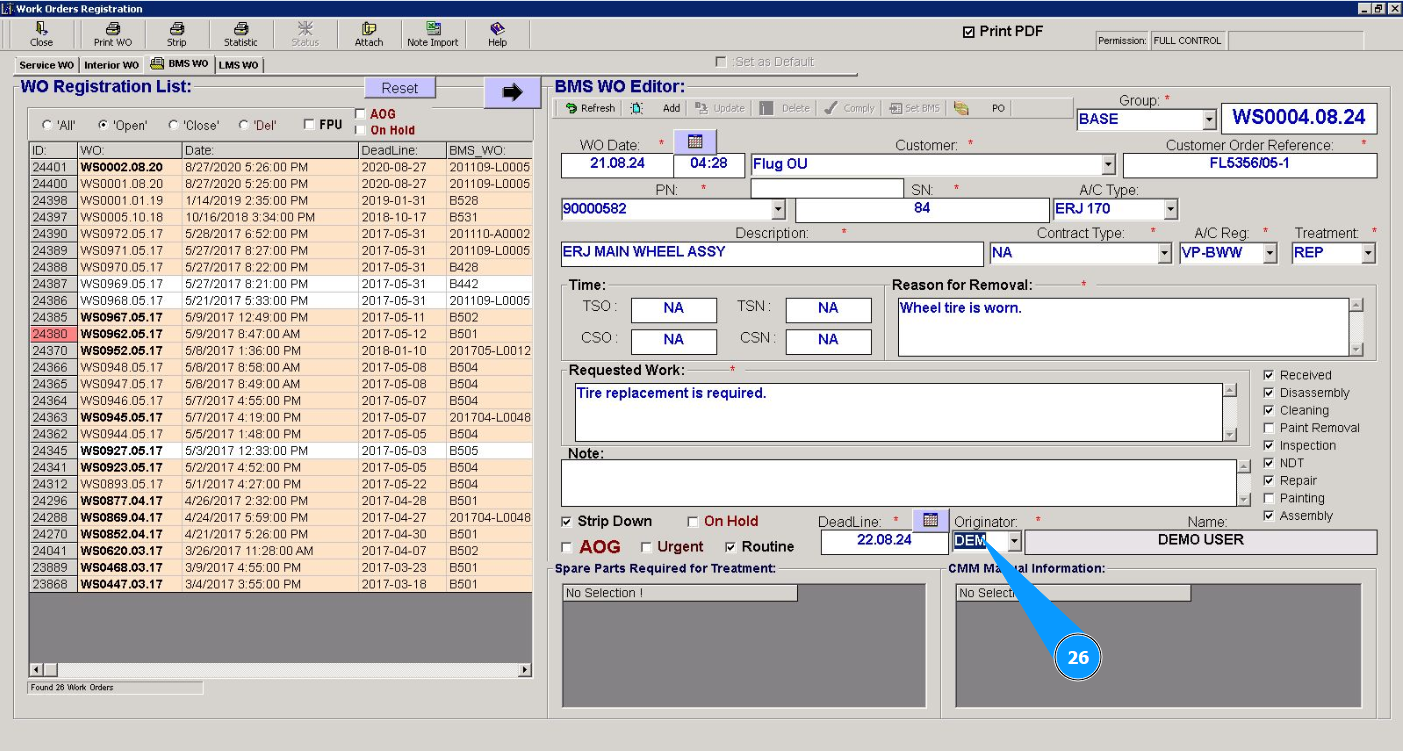

26. Select the initials of the performer or creator WO (in accordance with your company policy) from the dropdown list in the field "Originator". Note: The performer's first and last name will appear automatically in the field "Name".

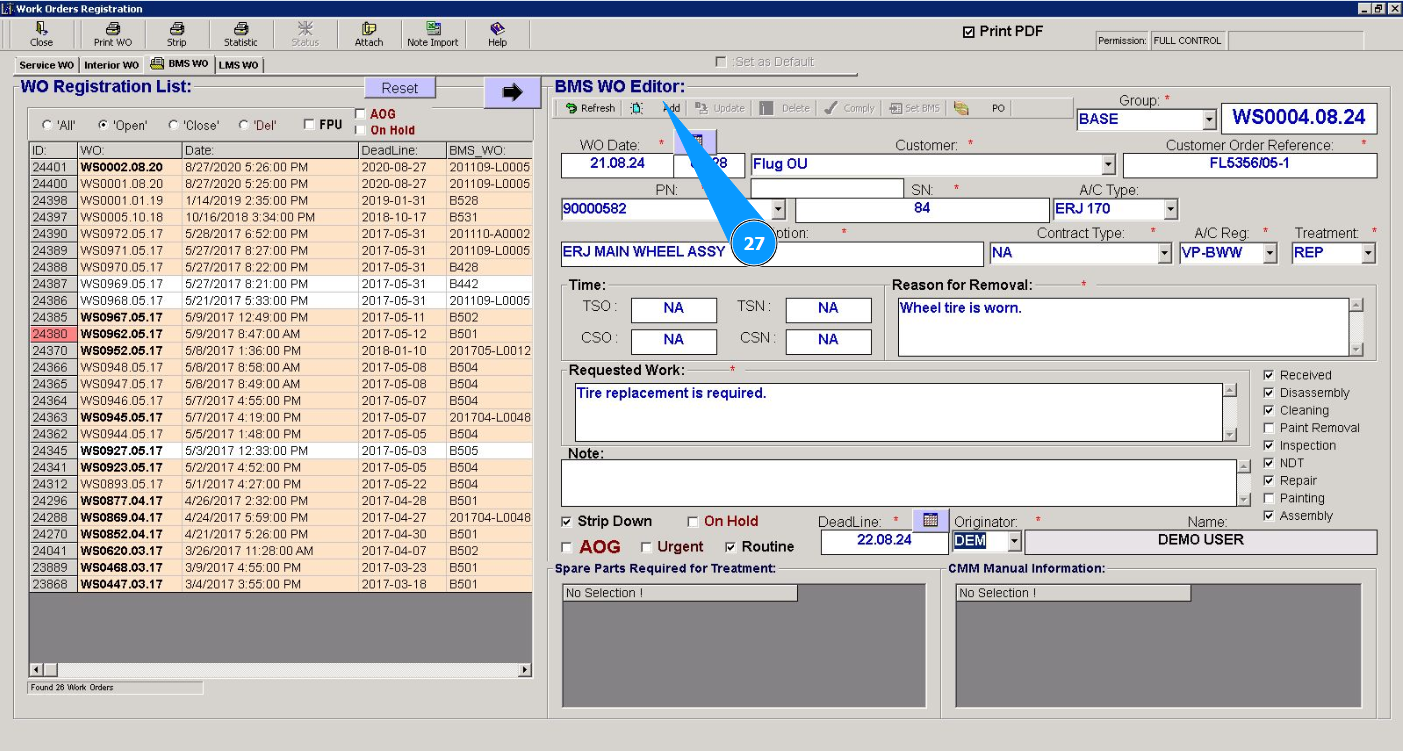

27. Click on the the button "Add" to add the order data for LMS to the program.

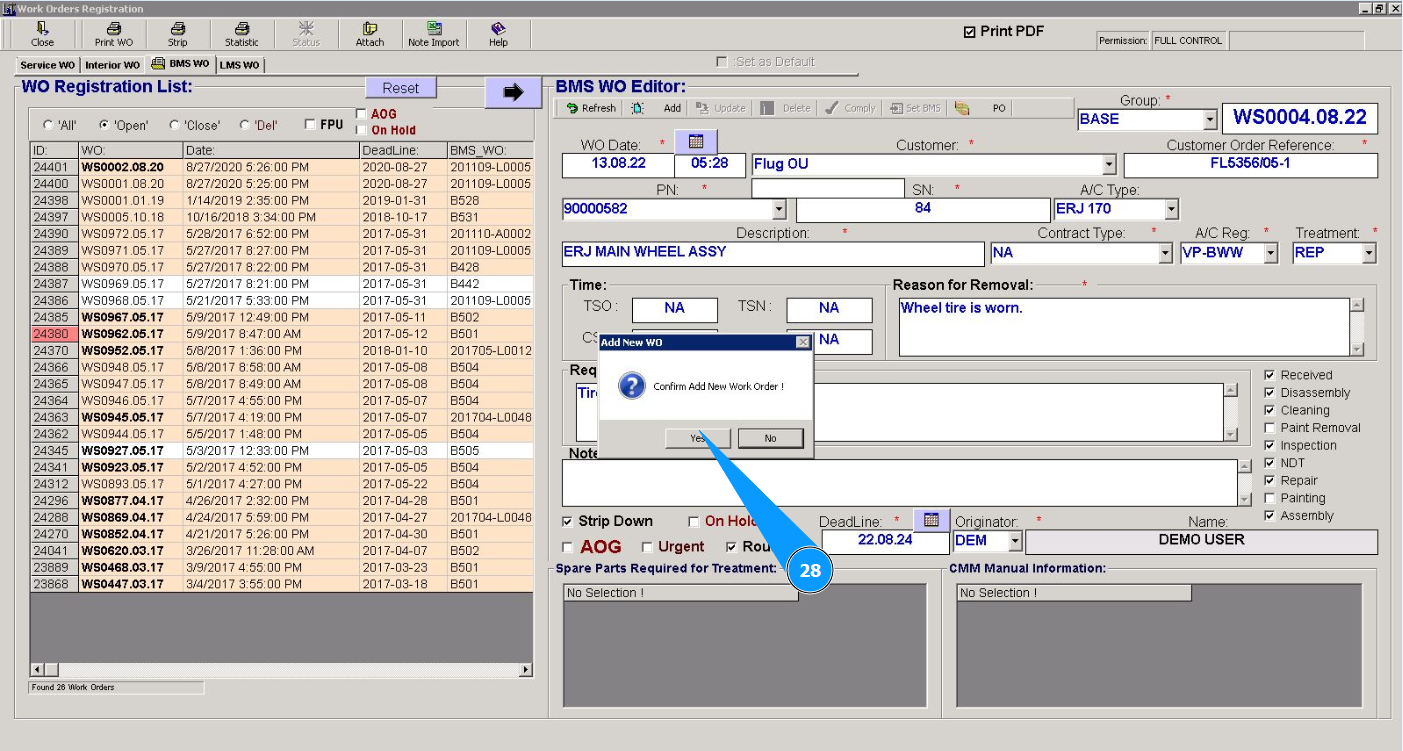

28. Clickon the the button "Yes" to confirm adding data to the program.

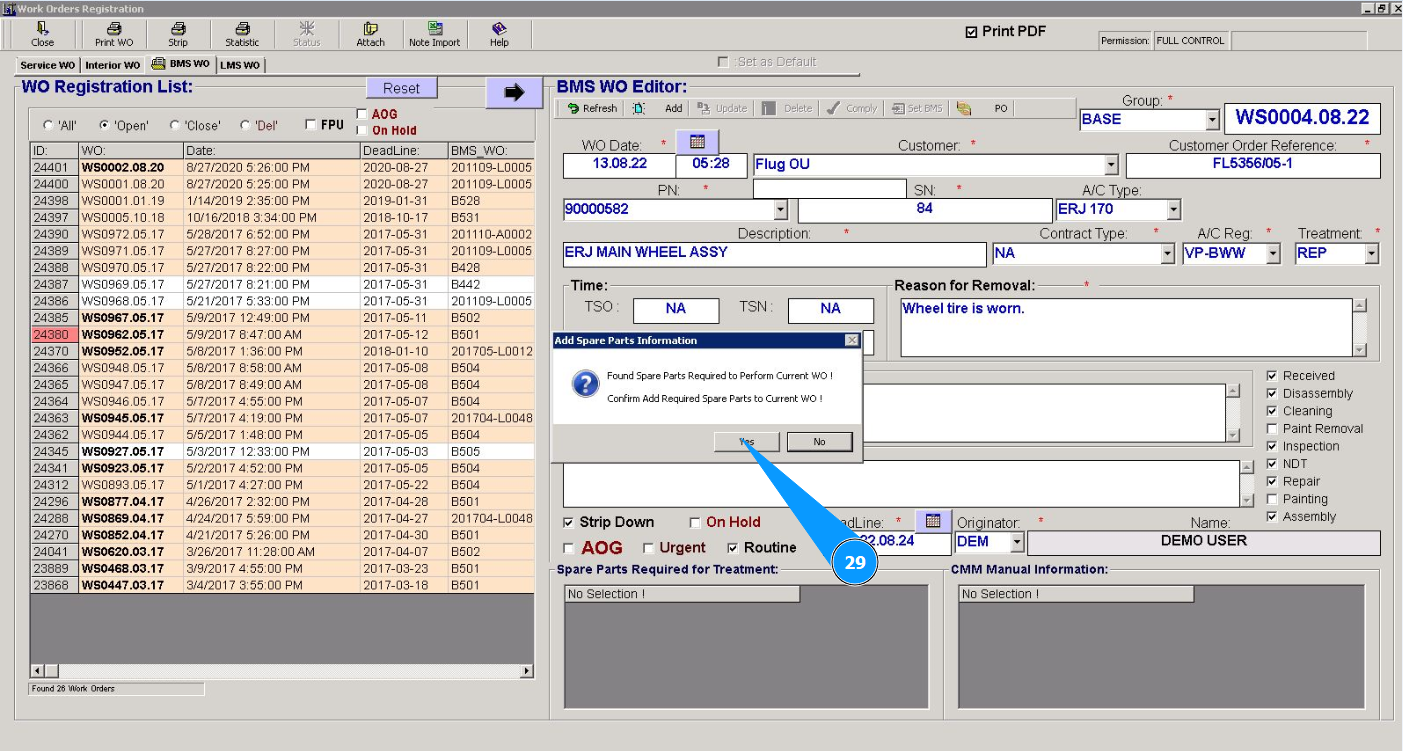

29. Click on the the button "Yes" to confirm the addition of previously entered spare parts to this work order.

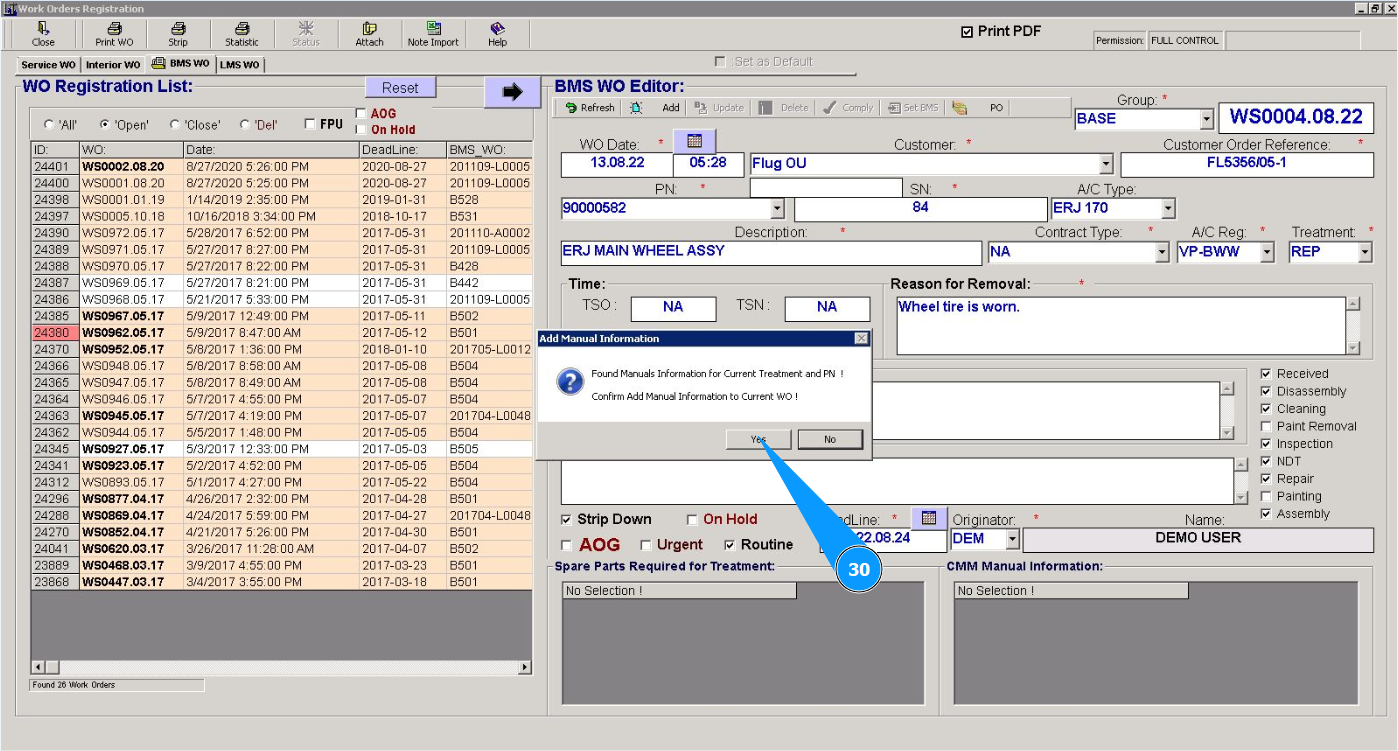

30. Click on the the button "Yes" to confirm the addition of previously entered materials for this type of work or part number to this work order.

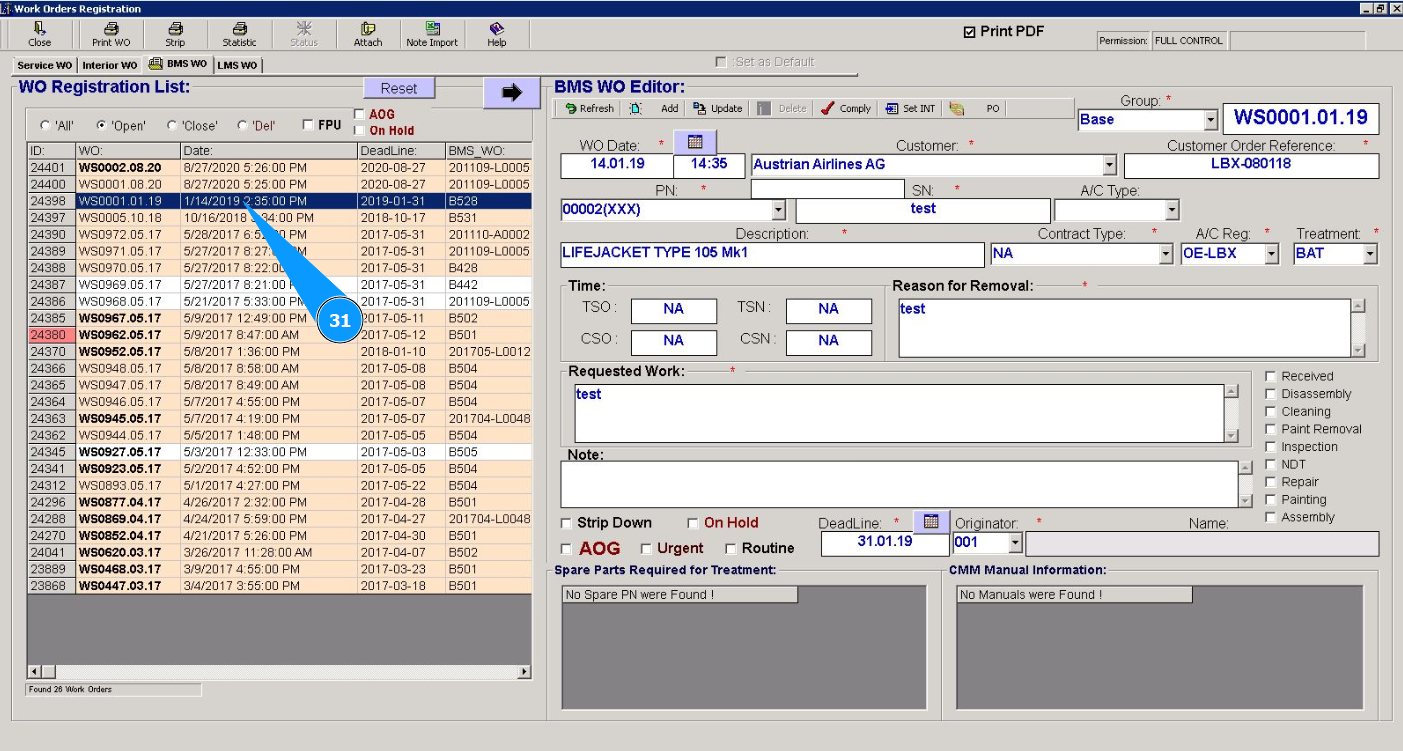

31. Check that the newly created WO is displayed in the window "WO Registration List".

Attention: If you need to immediately close this work order for base maintenance (Base Maintenace Shop WO), go to the corresponding instructions:

"How to close a work order for base maintenance (BMS WO)"